Oil & Gas

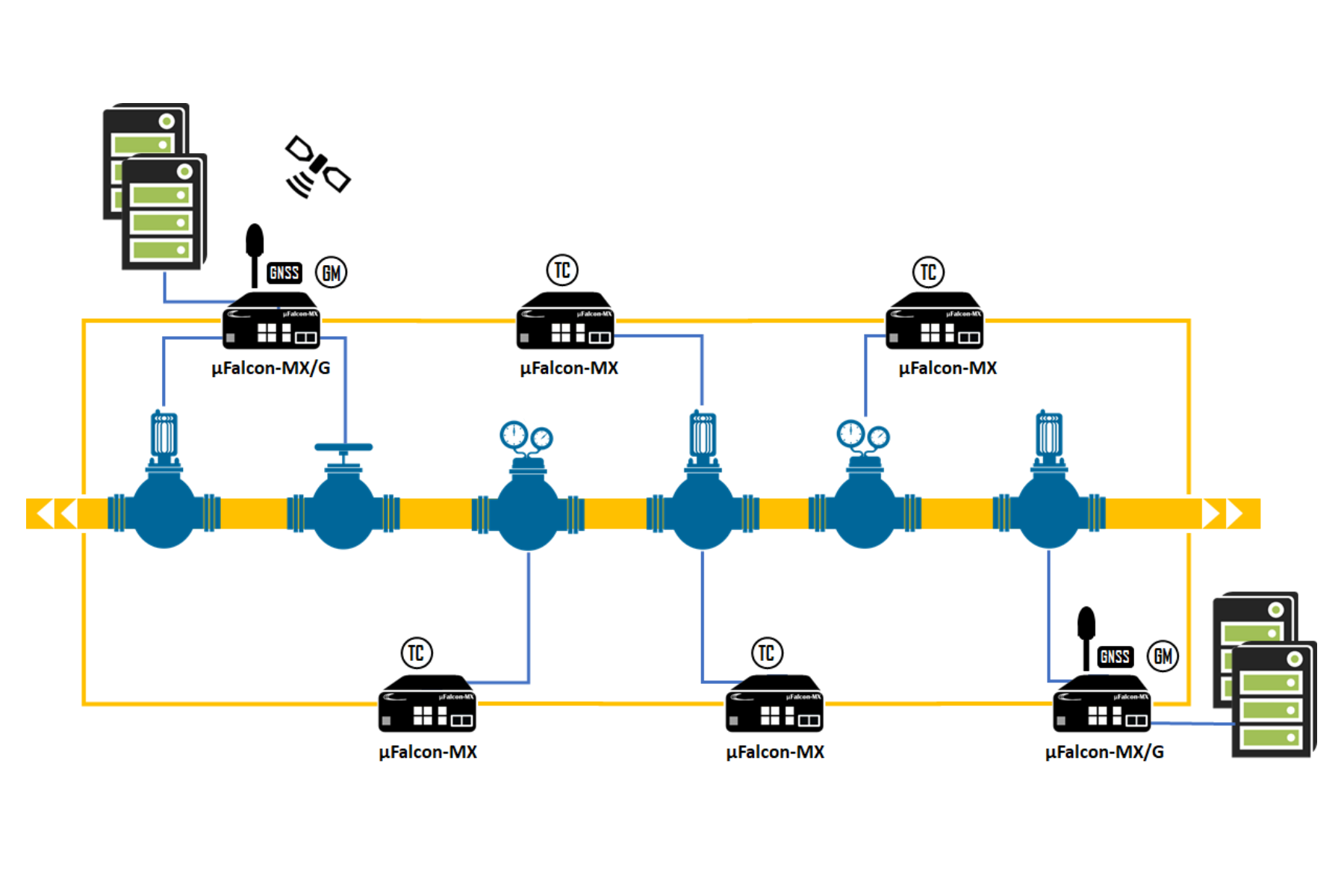

Moving Oil & Gas across a country (sometimes across continents) is done over very long pipelines, ranging to thousands of km. these pipes are supported by plentitude of pipes, valves and sensors of different kings; in order to ensure adequate, stable and energy efficient delivery, flow along these pipes must be regulated by a series of pumps and valves, controlled by servers that have to consider various parameters (such as temperature, pressure, flow rate) reported by sensors distributed along the pipes. However, in order to process and optimize the flow of liquid, all the devices along the line must be controlled as parts of one integrated system rather than independently. As propagation of the liquid as well as the electronic signals takes time, all inputs have no effect unless we can ensure they are taken on the same time basis or -in other words -synchronized. PTP IEEE1588 seems to be the optimal way to deliver synchronization along the line while assuming an IP network.

In any case you have to provide a network along the line for operational purposes (monitoring and control), security (cameras and proximity sensors), voice and more. Most likely a ring topology (on both sides of the pipe) shall be chosen for resilience. As the right of way is already given, the pipeline owner/operator may consider increasing the transmission capacity and provide bandwidth to Telecom service providers along the way,

Fibrolan’s µFalcon-MX series provides the building block for a solution that addresses both the Transmission and Synchronization issues.